HSE Management

HSE Management

HSE : Health, safety and environment

HSE Policy

DL Chemical is dedicated to the establishment and implementation of policies to protect life and the environment across all business sectors including

R&D, supply, manufacturing, sales, logistics and other service activities based on our core values of health, safety,

environment and quality in addition to constant improvement of product quality for customer satisfaction.

Code of Conduct

- 1. We consider the lives of all the people who work with DL Chemical as top priority, and provide accident-free workplaces by taking preventive actions.

- 2. We maintain our facilities and workplaces in the best condition, and promote our employee’s health.

- 3. All employees and contractors are committed to complying with all the laws, rules and regulations on HSEQ under the relevant jurisdiction.

- 4. We are committed to establishing a competent organization and structure to fulfill the core values of safety, health, environment and quality as we continue to endeavor to improve them.

- 5. We aim for the best quality products and services, and minimize the HSEQ risks through continual development of technology and workforce training.

- 6. We take social responsibility to protect the global environment by evaluating the safety, health and environmental impacts of all the processes of production and handling, and using environmentally friendly materials and technologies, and implementing ESG management.

- 7. We publicly communicate the policy with all employees as well as stakeholders, voluntarily carry out the HSEQ activities, and disclose our performance to all of the stakeholders to ensure management transparency.

This policy should be distributed to all employees and stakeholders, and initiatives promoting health, safety, the environment, brand quality should be encouraged.

It is carried out freely in accordance with the RC declaration, and openness is ensured by publishing the results to stakeholders.

It is carried out freely in accordance with the RC declaration, and openness is ensured by publishing the results to stakeholders.

CEO, DL Chemical

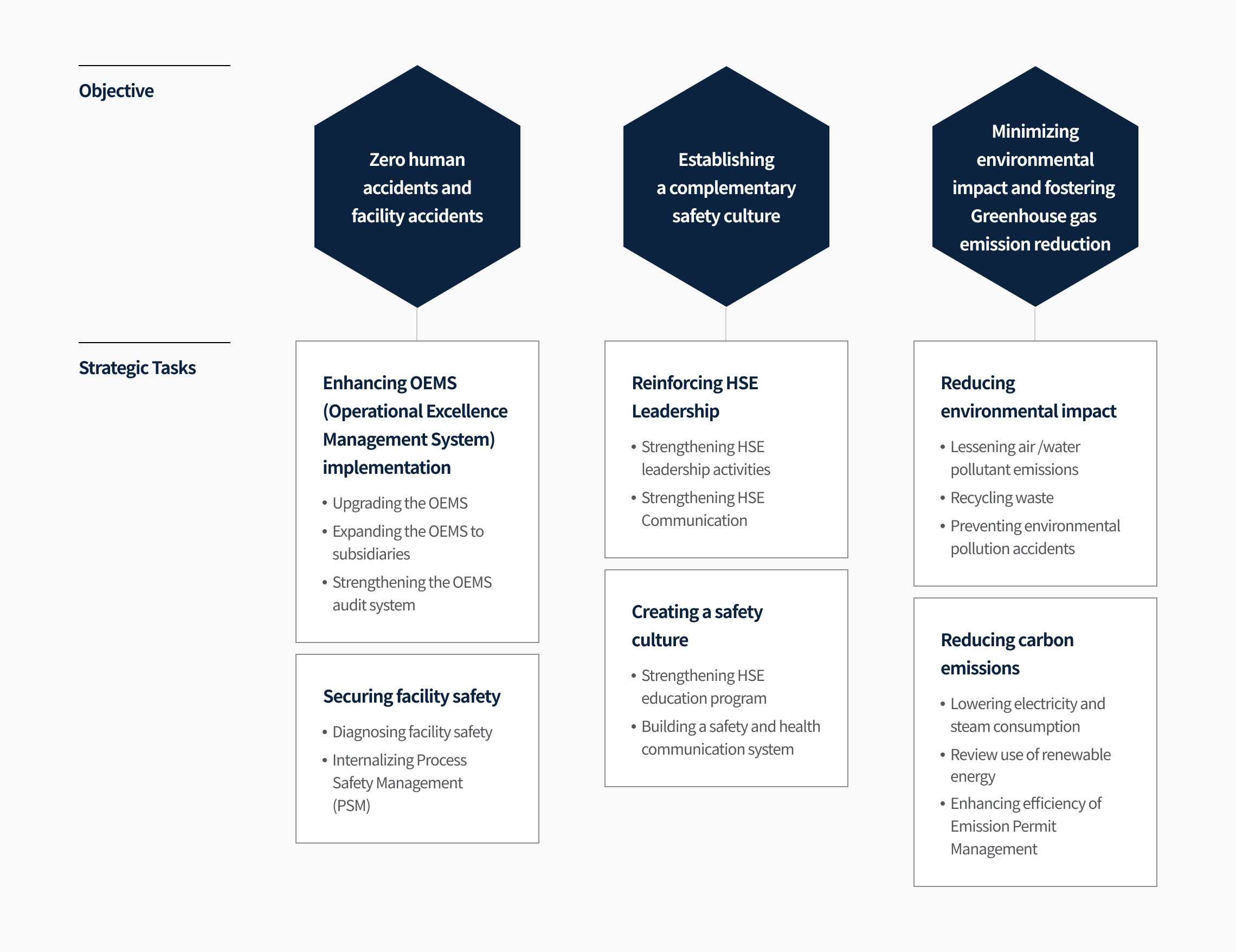

HSE Goals

DL Chemical strives for zero-accident and environmentally sustainable management based on worldwide leadership that prioritizes safety, health, and the environment.

HSE Management System

DL Chemical has established the OEMS (Operational Excellence Management System), a company-wide management system that meets international standards ISO (safety, health, environment, quality), PSM (process safety), and domestic regulations, and is appropriate for each element of operation based on leadership and the participation of all.

HSE Initiatives

DL Chemical has established and is operating ISO 45001 (Safety and Health Management System), an international standard management system, and is doing everything possible to prevent accidents and losses through risk management of safety and health.

-

Reinforcing Process Safety Management (PSM)DL Chemical is always improving the process safety management system's (PSM) operational level to prevent catastrophic industrial accidents caused by fires, explosions, and hazardous chemical leakage. We are strengthening asset soundness by diagnosing process facilities and investing in upgrading aging facilities, and we are increasing the degree of process safety management implementation by providing systematic training on the 12 elements of PSM.

-

Nurturing a safety first cultureBased on the 2019 safety culture diagnosis results, DL Chemical is carrying out tasks to increase the level of safety culture. Best practices and improvement cases carried out by each business unit are shared on the HSE Dash board for benchmarking and horizontal communications within the company We strive to improve corporate safety awareness and spread and develop a safety culture by carrying out duties such as enhancing management's safety leadership and establishing life safety rules.

-

Taking action in emergency situationsDL Chemical has procedures in place to respond effectively to emergencies. We hold emergency response drills regularly, based on the emergency response scenario, in which workers, partners, and local fire departments all participate. By running a disaster response team to for first action response to catastrophes, efforts are being made to reduce accident damage and prevent the spread of mishaps.

-

Supporting safety and health management of business partnersDL Chemical works with partner firms to improve safety management and reduce accidents. HSE meetings with partner companies’ representatives are held to increase suppliers' autonomous health and safety capabilities and to raise management's understanding of safety and health. Moreover, excellent suppliers are recognized by evaluating their safety and health performance, and a combined safety inspection team with suppliers has been developed to identify and address risk factors in the workplace.

-

HealthcareTo promote the health of its employees, DL Chemical has a health management program in place. We implement a specific follow-up management program for employees who are assessed to be in good health as a consequence of the health check-up. We are enhancing engineering and management work that puts a strain on the musculoskeletal system through the musculoskeletal disease prevention program. Furthermore, we protect our employees' and subcontractors' workers' health and create a pleasant working environment by monitoring the working environment and constructing prevention facilities or upgrading the working environment for processes that have a high level of exposure to dangerous variables.

Environmental Management Activities

DL Chemical has established and is using ISO 14001 (Environmental Management System), an international standard management system, to help preserve the local community and the global environment by reducing climate change and pollution.

-

Climate Change PoliciesDL Chemical proactively takes measures to tackle climate change systematically controlling green gas emissions and energy consumption. We report greenhouse gas emissions and energy consumption to the government as a corporation subject to the emission trading system, and we have designed and implemented greenhouse gas control systems. We are aggressively pursuing greenhouse gas reduction measures, such as optimizing use of processes and facility energy, to reduce greenhouse gas emissions.

-

Air Quality ControlDL Chemical probes on the level of air pollution at workplace on a regular basis to help improve air quality. Air pollution is systematically handled by employing in-house criteria for fine dust emission that are tougher than the regulatory standards, as well as a direct combustion facility monitoring system. We are fully complying with environment laws and regulations as we proactively carry out an array of environment tasks in addition to inspections and investments designed to reduce pollution.